Innovative recycling solutions for multi-layer packaging (MLP)

Multilayer packaging (MLP) plays a central role in the FMCG industry due to its superior protective properties and ability to extend product shelf life. This packaging technology combines the properties of a variety of materials to form a variety of functional layers, demonstrating excellent water and gas penetration resistance (such as oxygen and carbon dioxide), as well as strong mechanical strength and excellent low temperature resistance. These characteristics give MLPS a distinct advantage in protecting food and reducing food waste.

Multilayer packaging (MLP) does face challenges in recycling due to its complex structural design. Especially in some countries with inadequate recycling systems, the recycling of waste MLP is almost impossible to achieve, such as in India, due to the lack of effective waste collection system, waste MLP is difficult to be effectively recycled, posing a threat to the environment and public health. In the past, MLPS were generally considered "non-recyclable" due to their multi-layer structure, and the difference in rheological points of different layers of polymers increased the difficulty of separation.

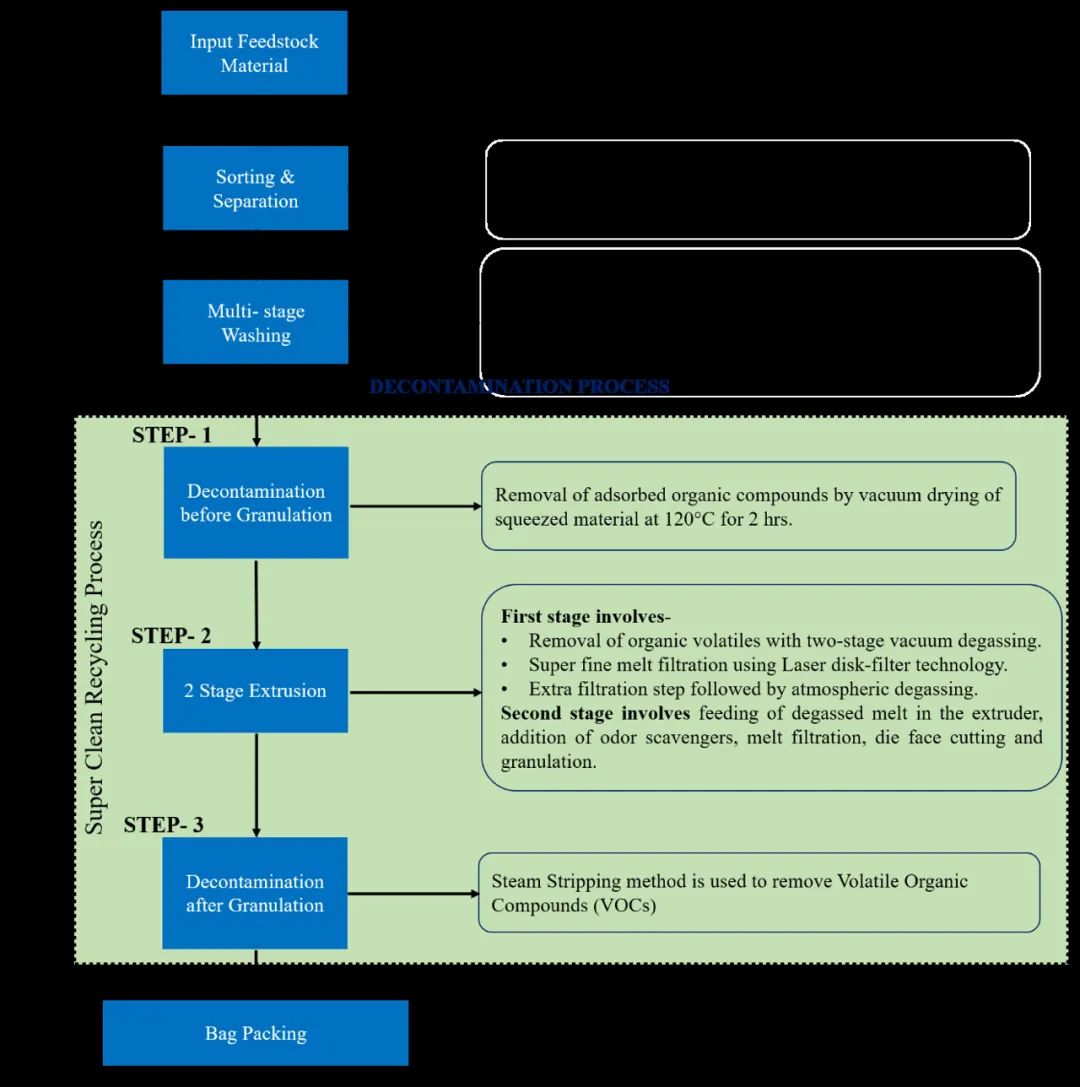

However, with the advancement of technology, the recycling of MLPS is no longer a problem. Modern technology has been able to break the "myth" that MLP is difficult to recycle and convert MLP waste into high-quality particles, which can be widely used in the manufacture of furniture, road dividers, bottle caps, pallets and other products, covering many fields such as industry and home furnishing. This transformation is thanks to innovative recycling technologies, including multi-step processes such as impurity removal, intelligent sorting, multistage washing, two-stage extrusion filtration and pelletizing, ensuring the quality of MLP recycling. The development of these technologies not only improves the recovery rate of MLP, but also contributes to environmental protection and resource recycling.

Structure analysis of multi-layer packaging

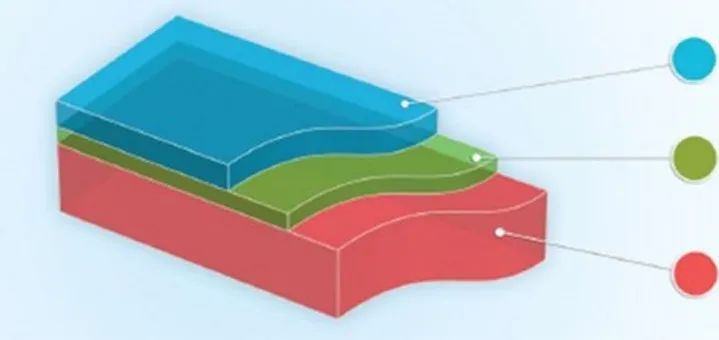

Multilayer packaging (MLP) is a composite material composed of multiple materials that combines different layers of materials (such as polymers, aluminum foil, etc.) in a variety of ways to form a structure that is both flexible and stable. The design of this structure allows the MLP to provide different protective characteristics such as barrier, mechanical strength and low temperature resistance as required to meet the packaging needs of various products. Figure 1 shows the typical three-layer form of a multilayer thin film structure. Each layer of flexible multilayer packaging performs a specific function in the application, such as:

Figure 1: Three-layer structure of multi-layer flexible packaging film structure

Outer layer: provides a printed surface, usually prepared from BOPP or PET material, which is both aesthetic and protective.

Barrier layer: This layer effectively prevents oxygen and moisture from penetrating and maintains the freshness of packaged food. Common materials include EVOH, nylon, METPET, METBOPP and aluminum foil, which have excellent barrier properties in flexible packaging.

Sealing layer: A low melting point polymer is usually used as a sealing layer, which can quickly melt and bond when heated, thus forming a strong connection between the different layers of the package. Polyethylene is the most common inner sealing film material in flexible packaging.

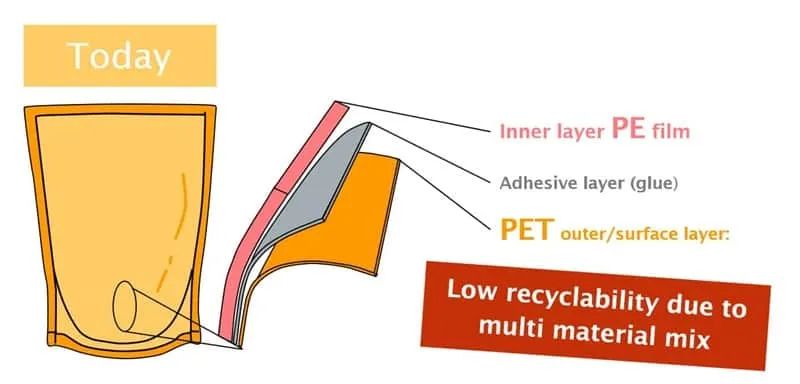

The layered chimeric structure of multi-layer packaging (MLP) gives it excellent performance during use, but it also brings a certain complexity to recycling. This structure makes MLPS excellent at protecting products, extending shelf life, etc., but the separation and reuse of different material layers requires more refined technology when recycling.

Obstacles to MLP recycling

Material separation challenges: MLPS are composed of multiple layers of materials with different rheological properties and chemical compositions, which makes it difficult to achieve efficient separation during recycling. For example, mixing incompatible polymers such as polyethylene (PE) and polyethylene terephthalate (PET) can reduce the overall quality of the recovered material.

Processing characteristics Differences: MLP layers have significant differences in melt flow rate and thermal stability, which requires specific recovery treatment conditions to be customized for each material, adding complexity to the operation and making it difficult to adopt a universal recovery method.

Inadequate sorting technology: Most current recycling facilities rely on manual operation or technology is relatively backward, and it is difficult to accurately identify and remove contaminants, which leads to low purity of recycled materials.

Lack of collection facilities: In many areas, no collection system has been established specifically for MLP waste, resulting in waste MLPS often ending up in landfills or incineration, resulting in a significant waste of resources.

The application of innovative recycling technologies

An innovative technology is changing the conventional view of multi-layer packaging (MLP) recycling by ensuring the quality of MLP recycling through a series of elaborate steps, as follows:

Removal of impurities: After MLP waste enters the recovery system, it is first removed by rolling screens, vibrating screens and vortex separators to remove impurities such as glass, paper and metal, laying the foundation for subsequent recovery processes.

Intelligent sorting: Use advanced AI sorting technology, including UV-visible, near-infrared, X-ray and other technologies, to automatically detect and remove non-polymer contaminants, thereby improving separation efficiency.

Multi-stage washing: Through multi-stage cleaning processes such as dry cleaning, hot alkali washing at 60°C, and high-speed hot washing at 60°C, high purity of recycled materials is ensured.

Two-stage extrusion filtration: A two-stage extrudation-vacuum degassing system with a 200μm laser filter and a 150μm disc filter removes volatile substances and further purifies the polymer melt to ensure high quality recovered particles.

Pelleting: Finally, high quality PCR-MLP particles are produced by extruder die molding, which can be widely used in industry and daily life.

Figure 2: Complete recycling process for MLPS

Application prospect of regenerated particles

The technology that breaks the "myth" of being difficult to recycle allows recycled PCR-MLP particles to show a wide range of application potential in a number of fields:

Decorative products: In the manufacture of decorative products such as plastic furniture and flower POTS, the ratio of PCR materials to raw materials can reach 60:40, which indicates that the proportion of recycled materials in these products is quite high.

Functional components: For functional components such as road dividers and bottle caps, the PCR ratio was 40:60, showing that recycled materials can also replace native materials to a certain extent while maintaining functionality.

High-strength applications: In products with high durability requirements, such as core plugs and floor tiles, the PCR ratio can reach 25:75, which proves the feasibility and reliability of recycled materials in high-strength applications.

In addition, these recycled particles are also widely used in the production of agricultural pipes, plates and tanks, opening up new possibilities for the recycling of plastic resources. The development of this technology has not only changed the old concept that MLP is not recyclable, but also promoted the development of circular economy, realized the efficient recycling of MLP waste, and provided a new path for environmental protection and sustainable use of resources.

Figure 3: Different applications of PCR-MLP particles