A domestic first! Coal-based POE has successfully achieved continuous preparation

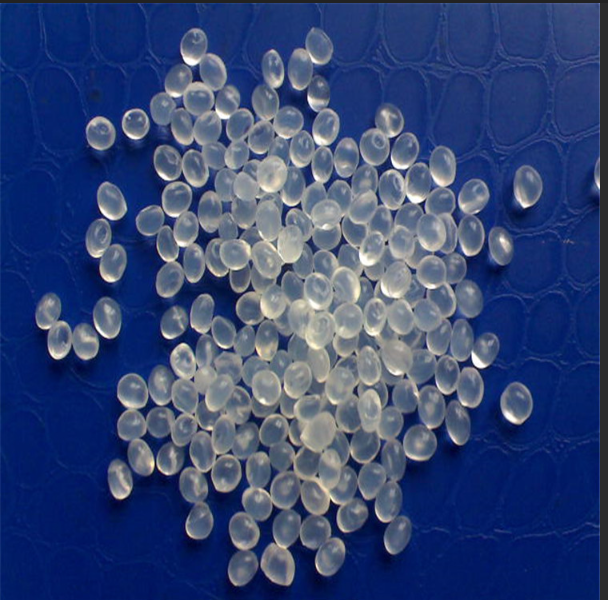

It is reported that recently, the Low Carbon Institute of the National Energy Group successfully completed the continuous preparation of coal based polyolefin elastomers (POE) for the first time in China.

The preparation process is a 10 ton/year high-temperature solution continuous polymerization device independently developed and designed by Low Carbon Institute. The raw materials are 1-heptene and 1-octene monomer separated by coal-based Fischer-Tropsch synthesis route. The polymerization activity of 1-heptene and 1-octene monomer synthesized by Fischer-Tropsch was slightly higher than that of commercial fossil oil octene monomer. The product composition distribution was uniform and the microstructure was similar to that of petroleum-based POE. The transparency and fog of the prepared film samples are equivalent to that of the products synthesized from petroleum based 1-octene, and reach the level of foreign photovoltaic materials.

In 2019, the Low Carbon Institute carried out research and development of Fischer-Tropsch α-olefin separation technology, and completed the development of 1-hexene, 1-heptene and 1-octene separation technology by the end of 2020, and the purity of the product reached more than 98%, which can meet the purity requirements of different commercial polymerization grades of α-olefin. In 2022, the Low Carbon Institute carried out the development of high temperature solution phase polymerization process, and supported the development of POE technology in Ningxia coal industry with the projects of "Research on polymerization conditions of ethylene and alpha-olefin solution" and "Laboratory Research on polymerization conditions of POE High temperature Solution". By optimizing the process flow of the continuous unit and improving the catalytic yield, the team systematically studied the influence of process conditions such as solvent, temperature, pressure and feed ratio on the polymerization process, and realized the coal-based POE synthesis under domestic conditions close to industrial production for the first time.

The continuous preparation of coal-based POE verifies the feasibility of applying coal-based high-carbon α-olefin to the production of POE and other high-end polyolefin copolymers, improves the economic benefits of Fischer-Tropsch's high-carbon α-olefin synthesis route, and lays a foundation for the high-value comprehensive utilization of Fischer-Tropsch high-carbon α-olefin products. Based on the raw material advantages of Fischer-Tropsch's α-olefin synthesis, this technology will promote the differentiation and high-end development of polyolefin products of the Group, further enhance market competitiveness, and help realize POE localization.